Graphic Art Mart now holds the exclusive distributorship of Massivit 3D Systems in Australia, with former supplier PES no longer involved.

Massivit produces large scale 3D printers, with Sydney-based Composite Images having purchased one of two in Australia, making the buy at its initial launch in drupa 2016.

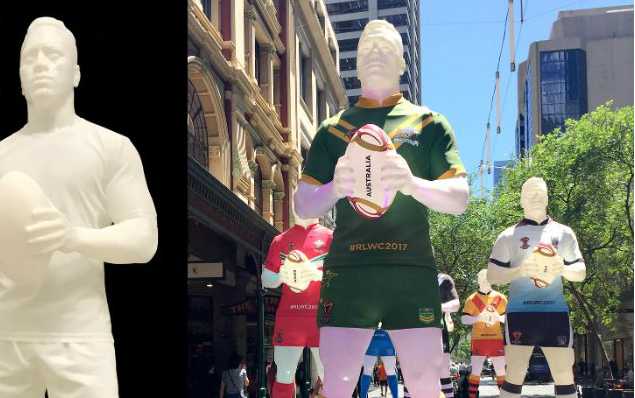

Composite Images 3D printed rugby league players for the 2017 Rugby World Cup,

Mike Liveris, branch and national equipment manager, Graphic Art Mart, explains, “We have taken on the exclusive agency for Australia. We are actively selling it now, and it is a whole new market for Graphic Art Mart. The crossover from static to 3D signage is a popular trend throughout the rest of the world.

“Massivit released it at drupa two years ago, and there are over 80 installs around the world. It has been strongly taken up, and two units are already in Australia, with Composite Images having great success with it.

“It is for channel lettering, and being able to illuminate the product itself is the biggest attraction, multiple lettering and strip lettering. You can produce your own tracks for soft signage, your own channel to whatever shape you want, and apply the fabric sample to the middle of it.

“Everything just becomes custom made, and bespoke pieces.

“Its size and speed are the biggest points. Traditionally 3D printing takes a long time to produce a small detailed piece, but this is printed at 30ml/s, dispensing the gel, building the model like spaghetti. You can have a finished product in minutes as opposed to hours.

“There are two sizes, the larger 1800, which is 1.5m x 1.2m x 1.8m high with a dual head or single head configuration. With the dual head you can print two different objects at once.

“The 1500 is 1.5m x 1.5m x 1.2m, and is available as a single head.

“Sign and display is where we are aiming, but it can be used for design of furniture, and is versatile. It is used in playsets for making props at size and scale quickly, while being rigid and lightweight at the same time. There are different markets, but we feel sign and display is the true hunting ground for it.”

For the Rugby World Cup, Composite Images used its Massivit 1800 to produce 2.4m models of players from each country, each using 18.5Kg of Massivit Dimengel Gel.

Liveris explains, “The printing time was 20 hours, utilising the Massivit 1800 dual print head technology multiple parts were produced at the same time, reducing the actual print time required when we printed the 14 models for RLWC.

“The model was printed in 8 parts to optimise quality and reduce the need for print supports.

“Parts were glued together using the Gel that they are printed from which is then cured with a UV light.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter