Many of the newly released inkjet presses released at drupa are due to become available in the next 12 months, with some already available, and more to be ready before the next drupa.

Heidelberg launched a B1 press, while Konica Minolta and Komori took the wraps off their collaborative B2 offering. Meanwhile, the Landa company had all eyes riveted to its B1 nanographic press technology.

The industry thinking is that if sheetfed inkjet can operate with consistency and quality at the speeds we are accustomed to from its litho counterpart, the use-by date for offset may well be brought forward. Of course, that prediction has been made many times over the more than two decades since digital commercial printing burst onto the scene.

But, as one inkjet press vendor put it, ‘with no plate production required and no need to run up to colour, makeready times and the associated waste are a thing of the past’.

And there is HP’s Indigo 10000, upgraded to the 12000, which, like nanography, is also strictly speaking not an inkje’ process but qualifies under the category for the purposes of its utility in that booming market.

Here are some of the latest offerings:

Canon – Océ Chroma

The Océ ColorStream 6000 Chroma is the latest addition to the ColorStream series and the product line’s flagship, says Tim Saleeba, general manager of Canon Professional Print. The engine is based on the ColorStream 3000Z, that is, it has the same speeds, print width and all the proven ColorStream features, such as waste-free print pause, printing in speed ramps, and variable page lengths or HeadSafe, all packed into the most compact hardware in its productivity class.

Compared to the ColorStream 3000Z, the new model features several new functions, which are collectively called the Chroma innovation package. These include the Chromera vivid pigment ink set for higher print quality or to enable the choice of a cheaper substrate for the existing quality compared to standard ink sets; an advanced calibration routine for less visible print head boundaries in large uniform areas through a better head-to-head adjustment during installation; PreFire digital refresh technology for less printed refresh measures, especially refresh dots, which would otherwise be more visible as background noise in the final print product, and an advanced PDF workflow support through streamlined processing of PDF/X4 and PDF/VT.

Saleeba says the business case for the Chroma is its wider application and media range. “To this end, it gives printers two strategic options – to leverage higher substrate flexibility, for example, by offering the same quality on a cheaper paper or add lightweight paper applications, such as pharmaceutical inserts, to the offering, and to offer higher print quality at correspondingly higher margins. With high-speed mono mode, black-and-white productivity can be enhanced by 20 per cent over the current highest speed 127m/min. This puts ColorStream users in a competitive position in higher volume segments as never before.

EFI Nozomi C18000

EFI’s Nozomi C18000 press has been its biggest inkjet product development to date, delivering lower costs and higher productivity in digital corrugated packaging, says EFI’s associate marketing specialist Mark Fletcher. With speeds of up to 75 linear metres (246 linear feet) per minute, producing up to 9,000 80 x 60cm boards per hour, this 1.8-metre-wide, single-pass printer is built and designed to target short-run, on-demand work in up to seven colours, including white, at a 360 x 720dpi resolution. At the same time, it can handle materials of up to 1.8 x 3 metres and thicknesses up to triple-wall board at full rated speeds.

Fletcher says if you had to choose one word to describe the nature and growth of current digital inkjet applications, it would have to be ‘transformative’. Consequently EFI’s range of inkjet technology continued to expand this year.

He says, “While digital inkjet’s leading performance is in applications demanding short runs, quick turnarounds and versioning and personalisation, there is more to the growth in new and emerging applications than just posters, signage and billboards. UV-curable, water-based inkjet printing continues to show increasing growth and EFI technology advancements now offer more speed, higher resolutions and more substrate options, considerably changing the digital inkjet equation.

“From printing on packaging, plastics and ceramics to laminates, textiles, interior design and décor, and personalised and customised short-run graphics, EFI UV-curable technology gives print providers a high level of flexibility and versatility, with the ability to print on nearly any type of substrate,” he concludes.

Fujifilm’s half-size alternative

Fujifilm makes its case for the J Press 720S by stating that it offers ‘a half-size solution for print runs of just one or thousands, where traditional offset and digital printing are failing to perform, and provides a superior solution for the fastest-growing segment of the market where the majority of print jobs reside and where the opportunities will be in the future’.

“It's the perfect solution for printers looking for a product that has the quality and robustness of an offset press, as well as the versatility to handle even the shortest of press runs,” says FujiFilm.

The J Press 720S prints a 74cm sheet in a single pass, resulting in production speeds of 2,700 sheets per hour, with printed sheets emerging dry to the touch. “This moves the breakpoint for the cost effectiveness of inkjet printing further into the traditional litho area.”

Use of standard coated and uncoated stock instead of specialised digital paper is another forte.. The standard stock, once imaged, can be treated like offset stock and simply dropped into existing finishing equipment.

Heidelberg’s digital prime

One of the lighthouse moments in print history has been offset mammoth Heidelberg’s embrace of high-speed, high-volume production-grade inkjet printing. Of course, the company has previously made forays into low-volume digital printing in the 1990s, but Primefire, its new inkjet press, is in a very different dimension.

Primefire 106 is seen as a cutting-edge drop-on-demand inkjet technology powered by a combination of Fujifilm technology, Heidelberg’s best-in-class sheet transport system, and full integration into Heidelberg’s Prinect workflow. Primefire 106 drives significant shopfloor process optimisation, as it not only enables printers to master shrinking runs and increasing variants, but also to respond immediately to changing customer requirements like different language versions, packaging sizes and last-minute changes. Primefire’s seven-colour inkjet system covers up to 95 per cent of the Pantone colour palette. Water-based fluids used are compliant with the Swiss Ordinance, a “must-have” for the production of low-migration food packaging.

HP upgrades Indigo to 12000

The 74cm HP Indigo 12000 – supplied in Australia by Currie Group – has been built by HP on its iconic HP Indigo 10000 technology, and says the company is an optimal fit in a hybrid digital-offset commercial enterprise. The 12000 feels at home on any substrate. The full sheet can be used to print canvas wall art, high-impact posters, folders, oversized books, specialty products, and more. Using HP Indigo’s liquid ElectroInk technology and unique digital offset process, as well as dozens of software and hardware innovations, the press delivers what HP claims as “the smoothest and sharpest prints in the industry, matching or even exceeding offset quality”.

HP Indigo ElectroInk has the widest digital colour gamut, says the manufacturer, reaching up to 97 per cent of Pantones and using up to seven ink stations on-press. A fifth ink station is standard kit. At a speed of 4,600 74cm sheets per hour, the press is capable of producing over two million colour sheets per month. Double-sided mono prints are generated at 4,600 sheets per hour.

Kodak Prosper 6000C and Ultrastream

With its smaller drop size and precise placement accuracy for higher resolution, clean lines and additional detailed definition, Kodak confidently predicts that Ultrastream will move production inkjet into the mainstream of commercial printing and packaging.

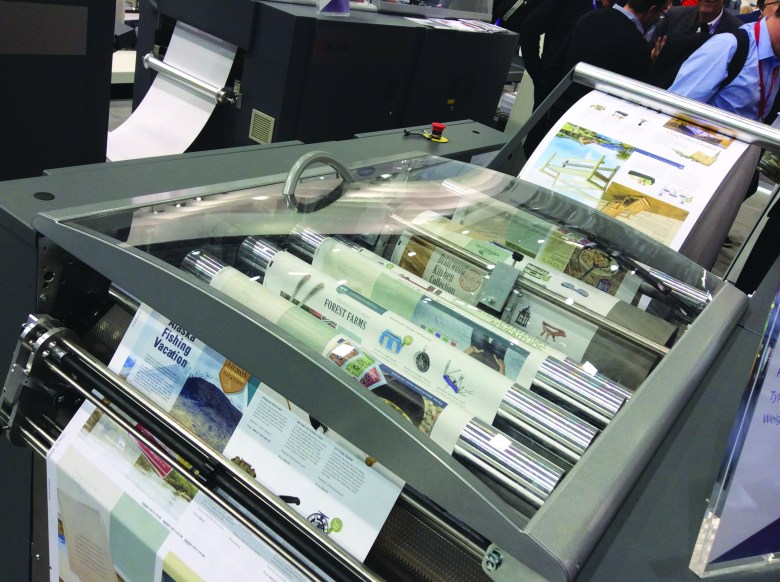

Kodak also used the show as a launchpad for its Prosper 6000C press with inline finishing. The press was demonstrated with a Megtec automatic roll splicer and multiple inline finishing solutions for both magazine/catalogue production, and commercial applications post-coated with an i-Web post-coater and finished with a Vits multi-cut variable servo sheeter.

New-generation ink droplet technology on the Prosper 6000C (cited as almost triple the speed of traditional drop-on-demand) opens new opportunities for production inkjet, such as long-run variable-data printing (VDP), according to Rick Mazur, Kodak’s worldwide director of sales operations.

The Prosper Press achieves up to 200lpi – quality that exceeds current inkjet technologies. And Kodak says it maintains its high-quality, accurate colour over long runs, thanks to in-system monitoring.

Komori’s Impremia

The press manufacturer, which is shifting into print-engineering service provision, offers its Impremia IS29, a 74cm four-colour, 1200dpi press, with a rated speed of 3,000sph – essentially the Komori-badged version of Konica Minolta’s AccurioJet KM-1. Komori sees the press as ideal for commercial and packaging printing.

Meanwhile, Komori used drupa to release its Impremia NS40 sheetfed press, a Komori-badged version of the Landa Nanographic B1 press. The NS40 uses NanoInk colourants in a hybrid of Landa and Komori technologies, with a rated speed of 6,500sph.

David Corbo, sales manager, southern region, for Ferrostaal Australia, which offers the Impremia exclusively in this market, says that in developing a digital printing system for printers' diverse needs and emerging market requirements, Komori focused on three important features – the ability to print with ordinary printing paper; to produce high print quality with volumes associated with offset, and to perform postpress processes immediately after printing (single-sided and double-sided).

He describes the lmpremia IS29 as a state-of-the-art digital printing system with a maximum sheet size of 585 x 750mm. “Digital printing in the 29-inch size greatly expands the range of work. The system prints large posters, paged items with multiple impositions and packaging that conventional A3 machines could not handle. Six-up US letter-size impositions are trouble-free.

Konica Minolta AccurioJet

Grant Thomas, product manager for Konica Minolta Business Solutions Australia, says his company positions the AccurioJet KM-1 as a press ‘and rightly so’. He says, “It boosts an impressive sheet size of 585mm x 750mm (B2-plus), and a format size that caters for a high percentage of commercial print requirements – all the while being able to print on heavy card stock at 0.6mm thickness for single-sided printing mode and 0.45mm thickness for double-sided printing.

“Printing at 1200 x 1200 for genuine offset image quality, and utilising a unique UV ink developed by Konica Minolta with LED curing, gives the output from the AccurioJet KM-1 an offset look and feel that is unmatched. Printing with UV ink, the press has one other unique positioning, no requirement to pre-treat or pre-coat the stock prior to printing. This feature alone opens the opportunity to explore new applications and to review opportunities via a full range of coated and uncoated stocks through to textured stocks, as well as packaging applications. And of course, variable-data functionality.”

Printing at an impressive 3000 B2-plus sheets an hour, with minimal downtime, means exceptional productivity from the KM-1 press. Thomas also notes that the rip technology was developed by Konica Minolta for the press from the ground up to maximise all the speed and functionality the press has to offer.

Landa’s nano-universe

As Michael Mogridge, sales director, Asia Pacific, at Landa Digital Printing, sees it, this year’s drupa marked the transition of its celebrated nanography process, developed by high-profile Indigo pioneer Benny Landa, ‘from a proof-of-concept, unveiled at drupa 2012, to a robust line of nanographic printing presses that address all major print segments’.

These include the Landa S10, a single-sided B1 press engineered for the packaging and converting industries; the S10P with perfector for two-sided general commercial printing; the W10 digital web press for short-run printing; the W10P, a new metre-wide perfecting press with two printing engines designed for the publishing, catalogue and direct-mail segments; and the Landa Nano-Metallography L50 module, designed for integration into conventional narrow-web label presses.

Mogridge tells ProPrint that between the low-volume offerings of digital and the high-volume offerings of offset, ‘there is a gap where neither offset nor digital printing is profitable. And in today’s market it is precisely these unprofitable short-to-medium run-lengths that account for the vast majority of commercial printing jobs’.

Ricoh’s versatile platforms

Ricoh has developed its InfoPrints on two platforms, for both General Production (GP) and Multi-Purpose (MP). InfoPrint 5000 GP models enable full-colour, monochrome and MICR printing on a wide range of paper stocks and at a variety of speeds. Colourful graphics and personalised printing makes information easier to understand, which can help open new revenue opportunities in fast-changing markets.

InfoPrint 5000 MP printers can be configured as a high-speed double-sided mono or entry-level duplex colour system. The MP printers are ideal for colourful transactional and promotional documents, as well as book printing and direct-mail projects. The InfoPrint 5000 General Production Platform (GP) is designed for environments with tight print windows and requirements for diverse media and stringent colour quality. A versatile platform, the GP models offer optional integrated or on-demand MICR for color or monochrome jobs. The speed of all models can be upgraded in the field. Ricoh says users can rely on proven inkjet technology – systems are in production around the world. Users can also expand colour possibilities with Patone Plus certification. They can get MICR support in colour or monochrome configurations, with PostScript, PDF, or AFP / Intelligent Printer Data Stream (IPDS) using the GP alone or paired with the InfoPrint 5000 Multi-Purpose Platform (MP) MICR model. Improve accuracy of print job estimates and monitor ink usage with the ink management suite. Gain page-level error recovery and accurate, consistent, device-independent output thanks to built-in Advanced Function Presentation (AFP) print architecture.

Screen GP jets ahead

Screen GP’s main focus for production inkjet within Australia is on the Truepress Jet W3200UV wide format flatbed/rollfed machine and the L350UV label web machine. That said, the company showcased two new versions of its Truepress Jet520 continuous-feed machine at drupa.

Now in its tenth year of production, the Truepress Jet520 range will be extended when released early next year with the new NX variation and the HD model that uses new inks, called SC for commercial-quality printing on coated papers, says Screen GP Australia’s managing director Peter Scott.

The Jet520NX features new five-inch printheads capable of 600 x 1200dpi. Speed has been ramped up to 150 metres-per-minute. It can be fitted with an extra printhead for a “fifth colour” that enables the use of MICR black ink, invisible UV fluorescent ink, and other special inks.

“The Jet520HD is aimed at commercial print, rather than transactional and direct mail and takes a paper range of 40gsm through to 250gsm, with a wide gamut ink set that rivals offset,” outlines Scott. “The Truepress Jet520HD has three different speed settings to balance print quality requirements and meet production deadlines. At the top speed of 120m per minute, the Jet520HD produces around 1,600 A4 pages per minute. At 50m per minute, full 1200dpi by 1200dpi resolution is used, combined with smooth halftone reproduction of four grey levels, resulting in stunning vibrant colour and very sharp text resolving power,” he adds.

Trillium from Xeikon

Offering variable web widths from 320mm to 520mm, Xeikon’s liquid toner-based Trillium, sourced locally through Absolute Electronics, provides high-speed, high-quality printing for direct-mail and catalogue production, offers full integration into a print workflow, prints on coated substrates, and has full rotary printing independent of the number of colours or the repeat length. Xeikon says Trillium One combines the strengths of offset litho in delivering high print quality, ink densities and image coverage on different substrates, with the strengths of digital printing to enable variable data printing at higher volumes with lower costs and easy operation. The joint development project between Xeikon and Miyakoshi combines the expertise of Miyakoshi in the mechanics of a printing press and Xeikon’s approach to digital imaging, high speed electronics, high resolution LED technology, workflow and toner technology.

Capable of running at 60 metres per minute at 1,200dpi, with a print width of 500mm, Xeikon says the four-colour press delivers cost effectiveness, high quality and speed. It uses Trillium, Xeikon’s liquid toner printing process, which was first presented at drupa 2012. Initially it is ideally suited to direct marketing materials and catalogues, with more target markets and applications expected to be added over time.

It incorporates Xeikon’s Tonnik, a liquid toner combining all the advantages of dry toner in a liquid format, making it environmentally friendly and economical. Trillium technology resulted in the small toner particle size of less than 2 microns used in the Xeikon-crafted high viscosity liquid toner. The toner contains no evaporating carriers for a more environmentally conscious print production process that also mechanically recycles the majority of the carrier liquid.

Shipping of the Trillium One will start from Q2 2017.

Prosper 6000C boosts US VDP house

Kodak’s new Prosper 6000C production inkjet press, showcased at this year’s drupa, has already become an important resource in the pressroom of US commercial printer Fenske Media.

The 59-year-old family-owned company in Rapid City, South Dakota, specialises in advanced digital multichannel marketing and digital print. The business creates highly effective campaigns by working with customers to mine the value of their data or acquire new data that precisely targets individual recipients and dramatically improves the response rates.

Dave Fenske, president and co-owner, tells ProPrint: “We thoroughly investigated all inkjet solutions at drupa and remain convinced that the Prosper 6000 and Stream technology from Kodak is delivering on its promise as the most productive inkjet press in the market. This is critical to propelling us to provide more effective print and cross-media campaigns for our customers.”

Kodak’s Rick Mazur, worldwide director of sales operations at its Enterprise Ink Jet Division, says that at drupa and beforehand, Fenske Media evaluated all the major inkjet players in the market. The process included a review of print samples and TCOP per page to ensure image quality and production costs were optimised and targets were met.

“We showed them, every day, multiple times per day, for two weeks, our consistent image quality on glossy and catalogue and magazine stock, running at full speed,” says Mazur. “Speeds were 650fpm on gloss, 1000fpm on Krujet — inline to the manroland foldline, running variable catalogues on the show floor. This was a presentation unmatched by any competitor and made the difference as to why Fenske chose the Prosper 6000.”

Fenske Media has used Kodak presses for many years before it invested in Prosper and Kodak’s Stream technology. Aside from its new Prosper 6000C, it also has a Prosper 5000XLi and a NexPress 3600. These share the production space with an eight-colour Heidelberg Speedmaster with coater. The new Prosper 6000C, with some of the fastest speeds and highest print quality on the market, makes it easier for Fenske to profitably produce longer variable runs than the competition, says Dave Fenske.

He credits the capabilities of the Stream inkjet technology in the Prosper press line with changing the digital print model and enabling his company to efficiently produce completely personalised print of the highest quality. “Our job is to convert intelligence into actionable insights that drive marketing activities.

“We start simple and work to validate the existing database, then we look at the various touchpoints by running modelling exercises to see if we need outside data, and then we bring the two together to take advantage of where each customer is in that particular moment and why they make a particular purchase. Our programmes are driven by this intelligence—not seasons or dates on the calendar.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter