The firm declined to reveal further details of its launch plans until the show in May.

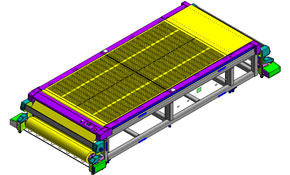

The enhancements to the JFX 1621, its 1.6×3.1m high-quality flatbed machine, include a roll-to-roll option, turning the machine into a hybrid and a post-curing system, a move which is designed to increase throughput.

Applications for the roll-to-roll system include cosmetic and fashion point-of-sale on flexible media, where extremely high image quality is required.

“Our roll-to-roll option is not the same as other systems,” claimed Mimaki Europe sales manager Ronald van den Broek. “We keep the media static on the vacuum bed, which ensures it is highly accurate. When both the head and the substrate move it’s hard to ensure accuracy.”

The two machines on show capable of handling 3D objects will be the recently launched UJF-3042 and the UJF-706.

“Until we launched the UJF03042, there was no small-format flatbed designed specifically for the application, and other machines are re-engineered from other devices,” said van den Broek.

He added that the machine, which has a print bed of 30x42cm and can handle objects up to 5cm thick, was also set apart by its LED-UV curing.

“LEDs are significant because they don’t cause heating, yellowing and warping, and many of the substrates in the market haven’t been designed for UV lamp curing.”

Mimaki will be exhibiting on stand C120 in Hall 12.

Read the original article at www.printweek.com.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter