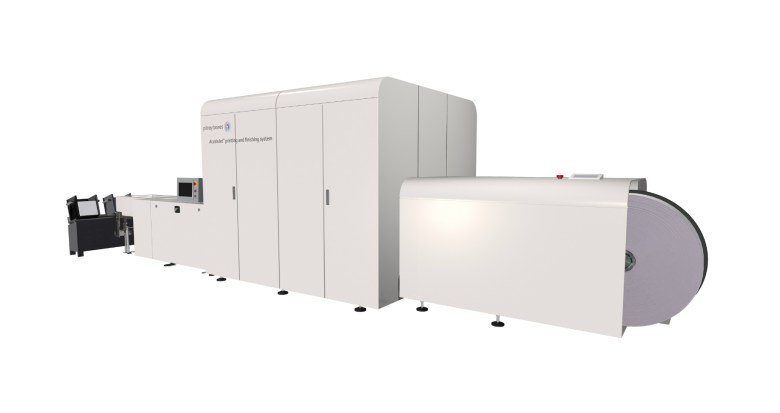

Pitney Bowes has launched a new roll to cut-sheet machine for transaction mail printers, which it says is a cost-effective path to high-quality colour inkjet. Jason Dies, president, Pitney Bowes Document Messaging Technologies, says the AcceleJet is suitable for printers that produce 4-10 million transactional or direct-mail printing impressions per month.

Dies says, “A number of mid-volume mailers with cut-sheet workflows are looking for a cost-effective way to transition to inkjet. Given our familiarity with these clients and our experience with production print in the complex transactional mail segment, we believe this is a space where we can add value. “Some of the world’s largest mailers rely on Pitney Bowes’ IntelliJet printing systems to produce billions of high-impact colour bills and statements every year. “Our AcceleJet offering leverages everything we have learned from servicing these high-volume mailers and makes it available to a broader market segment, which includes many businesses that already rely on our industry-leading inserting equipment.” The company says the AcceleJet system offers one-up roll, dynamic perforation, and cut-sheet output through a high quality, duplex colour inkjet print engine that fits within existing cut-sheet workflows. Dies says, “By combining the latest innovations in customer engagement software, printing and finishing, AcceleJet can be the centrepiece of a white paper factory – an end-to-end production mail solution that transforms plain rolls of white paper and envelopes into high-impact, colourful and personalised customer communications. “A White Paper Factory eliminates the need for pre-printed forms and envelopes, helping to streamline print and mail processes and lower operational costs while providing a means to add greater value to each mail piece. AcceleJet extends these benefits to mid-volume mailers in cut-sheet environments. “Increasing cost pressures, privacy issues, regulation, emerging technologies and evolving customer preferences are critical business issues facing print and mail operations. Pitney Bowes is helping our clients address these challenges with end-to-end solutions that fully integrate print and mail processes.”

He says AcceleJet produces full-colour, personalised communications with two-to-five-times greater throughput over existing monochrome, spot colour, or full colour cut sheet toner systems and features a wide range of built-in finishing options that allow more types of jobs to be processed on a single platform. “It can increase productivity by achieving greater speed and quality with dual print modes that let users fine-tune production to help meet even the most demanding colour quality standards and service level agreements (SLAs),” Dies says. “Other benefits include maximised efficiency with greater throughput, featuring a roll-to-cut sheet output including a high-capacity, dual conveyor stacker for continuous operation.” He says AcceleJet has advanced output flexibility through integrated finishing, including dynamic cross perforation, linear perforation, automated job separation, and servo-controlled precision cutting with high quality 1200 dpi perceived resolution. Pitney Bowes says printers can order the AcceleJet and finishing system directly from the company next week, and shipping is expected to begin in the fourth quarter.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter