Paper manufacturer Sappi says it has developed a low cost way of making lightweight nanocellulose material that will make its production commercial viable.

The material has applications across a wide range of industries and could be used to make paper and coatings, and as a replacement for plastic films in packaging.

Researchers at Edinburgh Napier University in Britain, who teamed up with Sappi on the project, say their technique for making Cellulose NanoFibrils doesn’t require expensive chemistry, and also doesn’t generate large quantities of waste water.

[Related: More paper news]

Lead researcher Professor Rob English says commercial interest is growing and it could have a global market of 35 million tonnes a year by 2020.

Sappi, which supplies paper to printers in Australia, is planning to build a pilot plant to produce the material in the second half of 2015.

Sappi Europe research and development director and project coordinator Math Jennekens says: “Nanocellulose, extracted from wood fibres, has a number of unique optical, barrier and strength properties.”

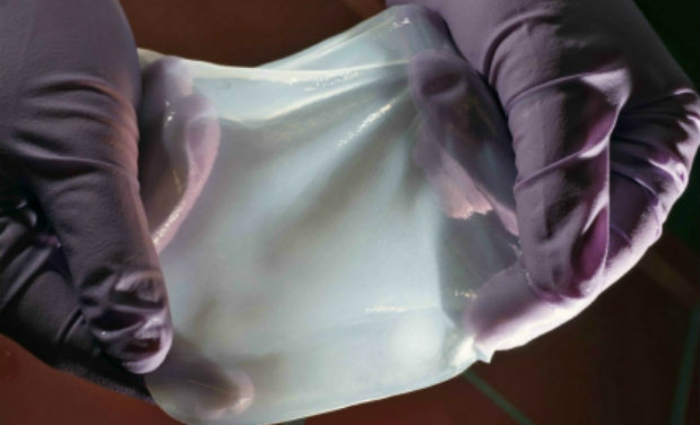

The versatile material is produced by intensively processing wood pulp to release ultra-small cellulose fibers – each so small that 2000 could fit inside the width of a single strand of human hair.

Jennekens also says the nano material is ‘completely sustainable’ unlike those based on fossil fuels, which made it attractive for a wide range of industrial applications. The material is also completely recyclable.

Sappi head of technology Andrea Rossi says the material ‘will move Sappi into new adjacent business fields based on renewable raw materials to produce innovative performance materials and help in delivering on Sappi's strategy to seek growth opportunities in adjacent and new markets’.

Applications outside of print include being used to build greener cars, thicken water-based products such as paints, foods and concrete, films in lithium batteries and touch screen displays, and replace glass fibres in composite materials.

As cellulose is inherently bio-compatible and bio-absorbable, it could also be used for biomedical applications like wound dressings and regenerative medicine.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter