At Drupa 2008, there were two B2 sheetfed digital printers: Screen and Fujifilm. At Drupa 2012, there were nine, with more to come.

Is there a need for a digital replacement for offset presses? Production digital printing is at its best when it implements full process automation, electronic collation, variable data, and inline finishing. Platforms that lack duplexing miss out on some of the most basic digital print advantages.

But there is a market for large-format static short runs printed on a multiplicity of substrates.

B2-format offset presses already provide high quality at very competitive cost on a wide range of substrates with in-line coating and perfecting units. Heidelberg, Manroland, Komori, and KBA have faster B2 makeready but that is only on new presses. Most offset machines are legacy presses with little or no automation.

Presstek puts platemaking on press with the 75DI, as does Screen. If applications fit in A3-plus format, there are many existing digital print devices to choose from. These have good four-colour quality at a fraction of the capital cost of the new class of B2-format digital devices. Many are aiming for offset press prices. Although they eliminate plates and makeready, they do have consumables costs and substrate limitations.

Two sides to the story

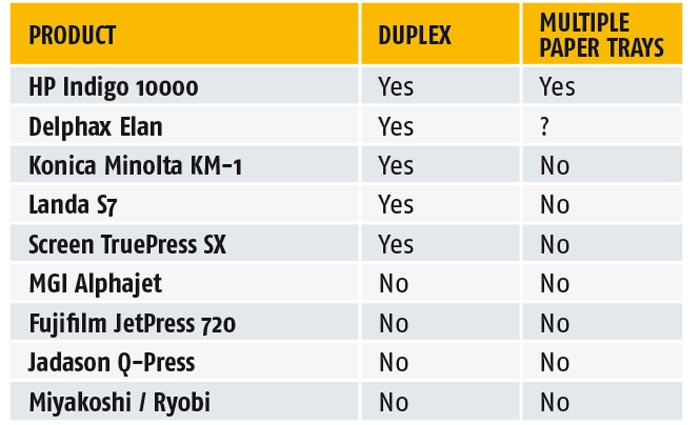

The new Indigo 10000 duplexes, draws from multiple paper sources, and is designed to support inline finishing. Delphax has also announced it is planning to add multi-feed capability (see the box for a list of vendors with B2 kit).

Packaging is a main focus of B2-format digital. Going to B2 format,

as long as heavy stocks are supported, opens up folding carton printing opportunities. This may be the best application opportunity for digital B2-format products, yet B2 may be a little small

for some packaging applications.

B2 supports a much wider range of carton sizes, but is limited for multi-up impositions of larger designs. Some packaging requires the use of brand colours and that could be a limitation. The Landa nanographic printers and HP Indigo can support brand colours.

Digital B2 and packaging were hot topics at Drupa 2012. But for production digital print services to move into packaging, the platforms need to be more than offset press replacements. They need more automation.

The new digital products may be best suited to do existing types of jobs. Around 98% of all digital jobs are static jobs but in shorter runs. Digital should allow you to do jobs that you could never do before effectively with traditional methods, but without duplexing or multiple paper sources, and with inline finishing in many cases.

The Landa and HP Indigo 10000 may have the best chances of success but we must see how it all turns out. The Indigo 10000 is available now but Landa is 18 months away. That said, hundreds of buyers put money down to be in the priority queue for Landa printers.

There is a need for large-format sheetfed digital printing, irrespective of technology. We can see that the market is evolving rapidly.

Frank Romano is professor emeritus at the Rochester Institute of Technology

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter