Australians have made the big trip across to Las Vegas to Connect 2018 gain access to the heads of digital software and hardware giant EFI, with Peter Wagener of Perth-business All Flags, and representatives from Ive Group, Blue Star and Kwik Kopy among those in attendance.

Wagener is a big user of EFI products, dating back to the start of his company two decades ago, when he was surfing the internet on a dial up connection trying to find information on printers to purchase. In 2017 he made a round of investments totaling $4m, including an Vutek LX3 Pro 3.2m printer, the latest grand-format Vutek 5r, and an EFI Pro 24F, which will be launched in four weeks time.

Wagener owns All Flags Signs and Banners (All Flags), he says, “I was at the Fuji Xerox premier partnership in Taipei last year and found that beneficial. When EFI suggested I come to Connect I jumped at the opportunity.

“Being able to look at what is happening, what is available, plus the advantage of being able to speak to multiple people in the EFI network brought me here.”

“I have everything from a VUtek 5300, which is 20 years old, an 18 year old 5330 5m solvent machine, the Gen-1 VabriVU, a QS2000, just put an LX-Pro 3.2m, the new VabriVU 340, and the new Vutek 5r. An EFI Pro 24F is on the way, due to be launched in four weeks.

“The latest generation of products are certainly more efficient. The information that feeds back from the machines and its ability to collect data is extremely helpful. We can look at our cost controls much better, run the machines more efficiently, and have more equipment running with less staff. They are more environmentally friendly, and better across temperature and humidity. We have less problems with colour shift over a major print run. The repeatability is a huge benefit for us.

“Every machine that they have on display in here I have. It is not like I am attending Connect just to look at new equipment, it is more about being able to speak to the heads of departments like Fiery. It is information that we do not normally get to speak in Australia, but speaking to some of these specialists is invaluable.

“Perth is isolated, seldom to people come to see us, reps will only come if there is something of significance. There are reps in Perth for small equipment, but not the stuff of the sort of scale All Flags uses.”

Wagener is using the latest version of Fiery, released September 2017. EFI says he is one of 70,000 to switch over, while Wagener says, “There are a lot of benefits. It can be run from workstations, allowing us to reconfigure our whole rip process, no longer do print operators rip, our graphics team rip the files from their workstations, which is processed directly to the hot folders, the print operators pick up the files and print them. It is a far more efficient process.

“Colour management is easier. We can print on any substrate, on any one of our machines, and if you put the print side by side, other than being matte, gloss, or satin, you would not be able to tell whether they were printed on a fabric, or on a board, or on PVC.

“We do major campaigns for multinationals across Australia. To be able to do textile, or a corflute promotional material put on a bollard outside, or a banner, or even vehicle decals, and have colour consistency across the print run, and across mediums, there are not many people that can do that. To be able to offer a customer that gives an edge.

“We have grown exponentially for the past four years, to the point where we had to relocate two years ago, have doubled in size since then, and looking at forward projections, we will increase our capacity by 50 per cent over the next 12 months. It is quite scary, going from managing a company of seven people eight years ago, to 31 today has all its challenges. If it was not for EFI and their equipment, we would not be there, and we would not be doing what we are doing. I have looked at other brands on the market, but they could not offer the complete range, with colour management, all integrated. It would have been a different company for a rip, different company for profiling, whereas with EFI it is a lot easier to solve any problems that come up, dealing with a single company.

“Our bottleneck now is in finishing. We have so much more capacity, and can print over 50,000 sqm in a 20 hour shift. We can not finish 50,000 sqm at the moment in an orderly fashion. So the question is how to get our finishing capacity to match our print capacity.”

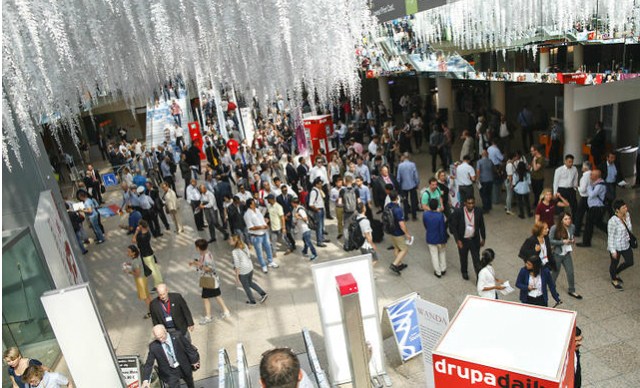

EFI Connect runs until Thursday in the US, it is one of the world’s biggest single vendor print solutions events, although there are plenty of partners at the show.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter