A new report from Smithers has examined the market for industrial and decorative printing, saying it is a rapidly emerging use of printing-for-profit in novel areas outside of the traditional graphics, commercial and packaging sectors.

Jon Harper Smith, author of The Future of Industrial and Decorative Printing to 2029, discusses the key trends and opportunities in this sector in this republished Q&A with the research firm.

Q: Which sectors and regions are seeing strongest growth for industrial and decorative print?

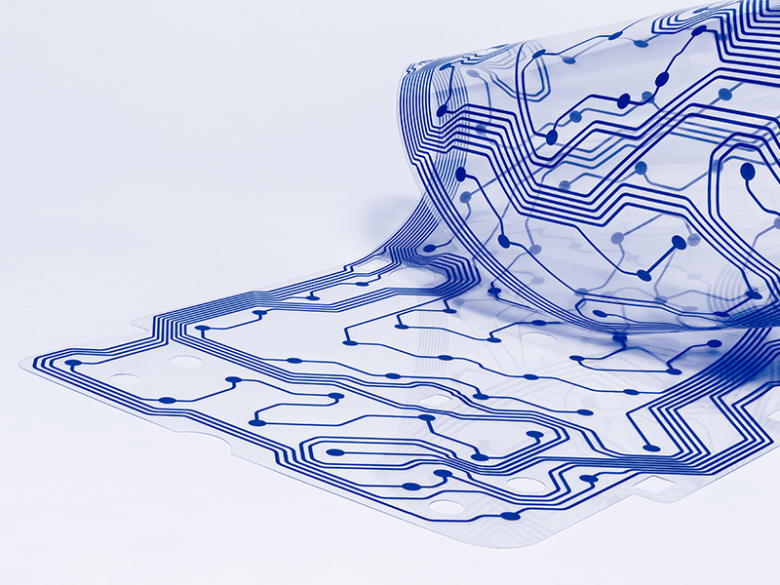

A: The segment with the highest growth rate is digital textile printing, which is forecast to grow by 9.5 per cent CAGR in volume and 9.0 per cent CAGR in value between 2024 and 2029. However, although digital textile printing is forecast to grow at the fastest overall rate, the highest growth in absolute terms comes from printed electronics which will grow by $23.8 billion, a higher number than all other sectors combined.

Asia is by far the largest region in 2024, and remains in a leading position throughout the review period, reflecting the position of China and other newly industrialised countries in the region as centres of global manufacturing. Japanese printers pioneered the commercialisation of many printed electronics applications, while South Korea is a leading manufacturer of flat panel display together with Japan and, increasingly, China.

North America and Western Europe are also strong regions for industrial and decorative print. Western Europe is a key region for development of many new technologies, including digital textile printing and high-quality ceramic tile manufacture.

Q: What key trends are impacting the market for industrial and decorative printing?

A: Suppliers have developed new equipment that widens the applications, with new inks, coatings and functional fluids providing new properties of flexibility, adhesion and durability. There is very strong growth in digital methods, with new inkjet inks and fluid opening many new opportunities for printing on plastic, film, glass, wood, metal, ceramics, textiles, laminates and composite substrates.

One of the megatrends impacting global development is the digitisation of manufacturing processes, the so-called Industrie 4.0 techniques. Print and finishing can be part of this, with the print providing some additional benefits in many cases with workflow controlling unique decoration and then tracking the item as it is delivered to a consumer in the case of a customised garment, kitchen splashback, wallpaper or even a car.

Q: What opportunities are there in industrial and decorative printing over the next five years?

A: There is consistent growth across most industrial functional print markets and regions, including the established analogue print processes. While the routes to market are very different to traditional printing, there are many opportunities for companies involved in the graphics and publication print sectors as well as equipment and consumable suppliers.

Growing demand reflects increasing demand for construction, automotive and generally manufactured products that are increasingly incorporating print.

The functional print market is extremely fragmented with many disparate organisations involved. As well as manufacturers, there are many start-ups that have identified applications and technology and are looking to exploit their expertise. There are also printing companies that are using their core printing skills in new markets; this development into industrial print applications is less common in Western markets but the situation is starting to shift as traditional publishing and commercial print continue to decline.

Q: What technical innovations can we expect to see?

A: Inkjet is the fastest-growing process in functional industrial printing, and there are continual improvements in reliability, productivity and new inks and fluids, all of which will open up many applications. Non-impact inkjet is very useful in industrial printing as the inks can be formulated to print onto virtually anything: the flexibility of inkjet allows irregular shaped objects to be printed with robotic carriers, or by moving the parts in front of the printhead.

Recent advancements in nanotechnology have led to the development of innovative classes of nanomaterials that are being integrated into printed applications. These new nanomaterials offer enhanced properties and functionalities, leading to significant improvements in various fields such as electronics, medicine, and energy. Examples include nanostructured conductors for electrical applications, nanomaterial based sensors and displays, wearable electronics, battery storage and functional coatings.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter