Click to see more details about each device down below:

CURRIE GROUP – HP INDIGO 12000 DIGITAL PRESS

CURRIE GROUP – HP INDIGO 12000 DIGITAL PRESS

HP says its 75cm format Indigo 12000 Digital Press produces the widest commercial application range, with superior print quality, high productivity, and wide versatility. Supplied in Australia by Currie Group and built on the best-selling and proven HP Indigo 10000 Digital Press, the press brings printing capabilities that extend high-value opportunities to grow business.

Promoted as an easy fit for offset printers, the HP Indigo 12000 Digital Press offers a solution for the digital printing of any commercial application on any substrate. It uses the full sheet to print canvas wall art, high-impact posters, folders, oversized books, specialty products.

Enabled by HP Indigo’s liquid ElectroInk technology digital offset process, HP says its Indigo digital prints are of the highest quality. The company says that by using dozens of software and hardware innovations, the press delivers the smoothest and sharpest prints in the industry, matching or even exceeding offset quality. HP Indigo ElectroInk has the widest digital colour gamut, reaching up to 97 per cent of Pantone colours and using up to seven ink stations on press. A fifth ink station is standard. Colour matching tools ensure colour accuracy and consistency.

Printing B2-sized sheets in colour at up to 4600 per hour, the press is capable of producing more than two million colour sheets per month. It also prints monochrome in duplex at 4600 sheets per hour. Sophisticated automation tools boost production efficiency and uptime. One Shot extends substrates to canvas, synthetics and metallised media. It prints on substrates from 70 gsm to 400 gsm and 75 to 450 microns in thickness— including coated, uncoated, coloured and dark papers, and paperboard for folding cartons. Use on-press HP Indigo ElectroInk Primer to expand printing possibilities on off-the-shelf papers.

HP says brands request Indigo for its high print quality, just-in-time production, and ability to engage customers by customisation and personalisation with variable data printing capabilities.

Available with the press HP PrintOS is a print production operating system with apps that help printers get more out of your HP Indigo presses and simplify and automate production. Use PrintOS to continuously improve operations. Access to the open and secure cloud-based PrintOS platform is available anytime, anywhere.

HP Indigo’s liquid electrophotography (LEP) technology, using HP Indigo ElectroInk with minute ink particles, delivers crisp linework, attractive images and smooth vignettes with a thin ink layer that gives uniform gloss between the ink and substrate.

Ricoh offers a complete portfolio of digital colour production cut-sheet presses from entry-level models – catering to those producing smaller volumes of high-quality print – to high volume models designed to handle a million prints per month. Ricoh says every model offers print quality, precise registration, support for a broad range of substrates, banner printing and dedicated Ricoh production service and support.

The most popular models in the Ricoh portfolio are the Pro C7100X Series that the company says suit the needs of small to mid-size printers. Versatility is the key to the success of the Pro C7100X – according to Ricoh the range of stocks and sheet sizes it supports, finishing options, and the added value of a fifth colour station provide printers the opportunity to offer customers a much broader array of printed offerings.

With a paper weight range of 52.3gsm to 360gsm, the Pro C7100X Series will run a diverse range of paper stocks, including coated and uncoated, recycled, coloured (including black), pre-printed, pre-punched, tab, envelopes, labels, letterheads, translucent, transparency, and synthetic material. Heavily textured media provides no challenge for the Pro C7100X Series with its AC-transfer system and elastic fusing belt technology transferring more toner to the media and improving image quality. It can handle a maximum sheet size of 330mm x 700mm enabling the creation of six-page A4 brochures or A4 landscape booklets.

Inline finishing choices include fully-finished professional saddle-stitched booklet making, punching, folding, ring binding and perfect binding. Mechanical registration ensures precise sheet-to-sheet and front-to-back image placement for easier finishing, whether inline or offline.

The Pro C7100X Series features a fifth print station with printers able to use neon yellow, clear gloss or white toner, to add value to documents and offer customers some special effects.

The Pro C7100X Series delivers image quality with a high print resolution of 1200 x 4800dpi, and a self-contained liquid cooling system that keeps the developer at a constant temperature to ensure colour consistency across a print run.

The press is available in two print speeds – 80ppm or 90ppm – and with a scanner option for multi-function applications, including copying and scanning. Dedicated Ricoh production service and support includes a customer care program and tailored operator training syllabus. It is backed by Ricoh’s TCRU program (Trained Customer Replaceable Units) which enables operators to replace more than a dozen part, to maximise uptime.

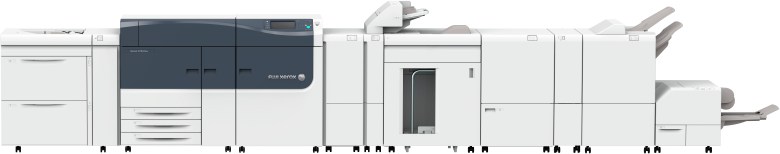

The Versant 3100 Press is for anyone who requires the highest level of performance and quality but does not have the print volumes of a Color 1000i Press or iGen. The Versant 3100 features a brand new D6 finisher with two edge trimming that can also complete three edge trimming with the combination of a squarefold trimmer. It also features creasing, with a new creaser helping booklet finishing and folding, giving smooth fine finishes to the spine, but it is only available on GXPS configuration only.

There is also improved specification with enhanced paper handling, extended paper sizes min 182 x 257mm and max 330 x 488 mm and weighs up to 350gsm. There is more productivity with buffering unit (for stapling and booklet making).

Featuring a rated speed of 100ppm on the heavy stock of up to 350gsm. Production Accurate Registration (PAR) gives consistent front-to-back registration, page-to-page, run to run, while Auto-Tray Switching, Auto Sheet Clearing and Reload-While-Run Capability keep the press running non-stop.

The Versant 180 Press is a smaller version of the Versant 3100 Press. The Versant 180 is directed at customers with average monthly print volumes up to 75,000 and prints at 80ppm on both coated and uncoated stocks up to 220 gsm. The all-in-one unit allows businesses to transform digital print operations, increasing productivity and maintaining quality.

Available from Neopost the Duplo DDC-810 Digital Spot UV Coater offers printers the capability to enhance images with a layer of texture and depth. Using inkjet technology together with an ultra-violet lamp to instantly cure the UV varnish, the DDC-810 applies a gloss finish to defined areas of the substrate giving them more impact and appeal.

A CCD camera, which automatically corrects for shrinkage, stretch and skew, along with registration marks ensures the accurate and precise alignment of the spot UV image onto the printed document.

Equipped with Duplo’s air suction feed system, the DDC-810 can process up to 21 ppm (ledger size) and 36 ppm (letter size). The unit features a dust roller, metal hydride lamp, ultrasonic double feed detection, fully automated head cleaning purge, and detection sensors for miss-feeds, ink attached, ink near empty, ink disposal tank full, cover open/closed, jam before and after UV lamp, and feed empty. Neopost says it is easy to set up and operate, and says the DDC-810 is ideal for short to medium digital and offset jobs.

KONICA MINOLTA MGI 3D JETVARNISH

Konica Minolta has a focus in postpress for digital which is about adding value, services and increasing the opportunity to generate client satisfaction that in turn translates to business growth. Konica Minolta’s MGI 3D Jetvarnish EVO offerings can produce a traditional 2D Spot UV effect, a raised 3D Spot UV effect, and a hot stamp foil all on one unit. They come in four different widths (364mm, 520mm, 640mm, 750mm) to suit different sheet sizes and 1200mm length.

The demand for differentiation by commercial printing clients is on the increase. They have a need to achieve greater results from their marketing spend and to separate themselves from their competition. Postpress functions such as Spot UV and foiling effects have been a means to achieve this in the print industry for some time. Now the MGI 3D Jetvarnish Evo brings this postpress offering via a digital workflow. Along with it comes all the advantages of digital printing such as shorter runs, variable data and versioning, no costly dies or make-ready, the ability to make last minute changes and ease of use.

At PacPrint 2017, Konica Minolta announced the official launch of the MGI 3D Jetvarnish. The MGI 3D Jetvarnish has many new advances redefining what digital spot UV and foiling can offer its users in postpress workflows to add new revenue streams. For the commercial printer that installs an MGI Evo, they have the opportunity of in field scalability. They can upgrade from Evo 52 (520mm) to an Evo 65 or 75 according to their growth, and how their business changes. This maximises the lifecycle of the equipment as well as increases productivity.

The raised Spot UV and foil effects can be produced at a height of up to 200micron. This feature alone opens discussions with clients to produce high-class print work. Around the globe, users of the MGI Evo technology are opening new markets for example; braille, short run embossed covers, point of sale material or targeted marketing pieces.

A recent infoTrends study commissioned late 2016 Beyond CMYK: The Use of Special Effects in Digital Printing highlights the value of offering postpress special effects. Konica Minolta believes the return on investment speaks for itself.

The Kurz Group says it is synonymous with the highest quality stamping foils and tools. The Luxor/Alufin foil range comprises of an extensive and diverse range of formulations and colours for all sectors of the graphic industry. Decades of experience in research and development combined with the most modern production techniques has ensured Kurz continues to lead the market in decorative and functional foils across the globe. Kurz says its M-Series hot stamping foil range, has been well received since its launch into Australia and New Zealand, The M-Series has been further strengthened recently by further development to deliver even more impressive stamping results. The new M-Series range now includes several products. The MTS is an all-rounder that delivers quality results and high abrasion resistance for a wide range of applications. The MTC has been specifically developed for uncoated stocks and provides high coverage on even difficult uncoated stocks, while providing print quality. The MTH is another specialty foil designed for precise edge definition on uncoated materials. The company says ML offers fine definition on smooth surfaces, and performs well on difficult substrates with limited surface tension. The MTU provides a solution for printers who require a foil to be applied over UV varnishes or laminates. GIO Pro is the premium overprintable foil. A further development is GIO N that provides improved workability while maintaining overprintability.

KPW OP also known as cold foil is the gold standard in cold foil. These foils provide workability and offer overprintability. The KPW OP range has continued to evolve to meet the ever increasing demands of a diverse market where label presses have increased production speeds and the requirement for improved print quality is expected. Metallic Red is now available ex stock in both Australia and New Zealand as a cold foil.

Supplied by Currie Group the Horizon BQ-480 Perfect Binder features a higher level of automation, in addition to dimension based automation, including customised automated setup accounting for paper type, signature vs loose sheet, sewn book blocks, notch binding, and other key factors for higher quality with less effort. With a maximum speed of 1350 cycles per hour for EVA and 1000 cycles per hour for PUR. It also has a book of one production capability, with maximum production speed of 800 books per hour for book of one production. The production speed changes depending on thickness change from book to book.

Its gentle boom delivery system is a book delivery mechanism delivers the book gently for high quality books, even with 65 mm thickness books or PUR bound books. The BQ-480 has a selection of glue types supporting both EVA hotmelt glue and PUR hotmelt glue. Two tanks are available for each glue type.

In the book feeding section, a rigid clamping system holds the book block firmly in position during the milling and nipping process to produce a quality finished book. The safety beam ensures risk-free operation. The spine of a book block or signature for optimum glue penetration and adhesion. Milling rotation speed can be adjusted automatically according to book thickness and custom template. Milling depth can be adjusted from 0mm to 4mm. Its glue tank section has dual application rollers and side gluing rollers ensuring superior glue application to the spine and excellent adhesion of the cover for consistent quality binding. Glue roller height, wiper opening and cut-off timing, scraper roller height, and side glue roller width are all automated. The nipping section is a strong rigid nipping mechanism and positive jogging guarantees precise alignment of the cover to the book block and square spines. Nipping width, height, operating time and delay time are adjusted automatically according to book thickness. The cover registration section is used after transport to the nipping section, the cover is registered precisely with the fore edge guide and tail edge positioner. The system features various functions to improve production and quality.

MORGANA DIGIBOOK PUR PERFECT BINDER

Over the past 10 years Morgana has seen a shift towards PUR binding to reduce uncertainty of glue binding reacting against varnishes, toners and varying paper types. Unfortunately, PUR binding also comes with an increase in cost for the print buyer due in part to cost of long make ready, wash ups and glue wastage for each shift of PUR binding.

These issues have been addressed by Morgana within the Digibook range. Morgana has developed a range of PUR binders which are ready to use in 25 minutes from first start up and are cleaned in less than five minutes with almost zero glue wastage.

This is only possible through a closed glue tank utilising a slot applicator to deliver glue to the book on demand. Morgana has put a lot of R&D into this and have seven patents on the glue system alone. Morgana says the simplicity of this system means that any print shop or finishing house can perfect bind books on demand each day or as required by the customers.

With Morgana it is feasible to bind 10 books in the morning then clean up and then if you receive another order the same day, simply heat the machine back up and bind more books. Morgana Digibook range covers four levels of production with entry level being 150 books per hour through 200 to 300 finishing at 450 books per hour. Digibook 150 and Digibook 200 are so versatile they plug into standard electrical power points.

The closed glue system allows for the machines to be operated without the need to extract glue fumes, which means the machines can be operated in almost any location.

Xeikon says its CX3 digital colour press, originally known as the Cheetah, is 60 per cent faster than any of its toner-based label and packaging stablemates. The new digital press is dedicated to self-adhesive and pressure sensitive label production, and can produce high quality labels at 30 metres per minute. Xeikon says this running speed makes it the fastest five-colour digital toner label press in the world.

This increase in speed represents a leap forward in digital toner press technology. The Xeikon CX3 narrows the gap between digital printing and traditional flexo and offset methods for producing labels and that increase in speed results in a lower total production cost.

The Cheetah can handle substrate widths of up to 330mm, with resolution of 1,200 x 3,600dpi.

The Xeikon CX3 is designed to give label printers and converters greater flexibility to deal with shorter turnaround times.

Like all Xeikon presses it uses full rotary printing, where press speeds are independent of the number of colours used and the repeat length of the job. The stability of full rotary printing also makes step-and-repeat and finishing operations straightforward.

It uses dry toners that meet FDA regulations for food contact, and can use conventional substrates without any pre-treating. The toners are also high in light fastness, ranging from 6.5 to 8 on the blue wool scale.

Xeikon’s labels and packaging machines can print opaque white toner in one pass.

A fifth station on the Cheetah and other Xeikon presses can be used to print gamut expansion colours or security toner, as well as the standard CMYK plus white. The white has a high opacity similar to the screen white. Other gamut expansion colours available include red, blue, green, orange and clear. Xeikon says these colours can be easily swapped as required without any need to wash up.

The press includes automatic inline register and density controls, imaging width is up to 322mm while repeat length is variable from zero to 55 metres. Media weights range from 40gsm to 350gsm with thicknesses from 40um to 550um.

Depending on the application, the presses can be optioned with a number of finishing solutions, including an inline aqueous or UV web varnishing module, sheeter and stacker.

Screen says its inkjet label press has been a hit worldwide, including in Australia where it has been the best-selling inkjet press since its release in 2013. Screen has a reputation for making well-engineered products and the says L350UV does not disappoint, with a reliable consistent high quality performance, as you would expect from a company with Screen’s engineering pedigree. Screen launched the extended press range at LabelExpo Brussels, with the current model being joined by two new variants. The L350UV+ is an additional model that offers the ability to print thinner materials in order to meet the requirements of the packaging industry. An additional colour (orange) is also offered to extend further what Screen says is the already impressive colour gamut, which Screen achieves through its prepress experience.

The second new model (L350UV+ LM) adds a low-migration Food- Packaging Compliant ink series, which uses nitrogen to aid the curing process, in order to meet the most stringent non-direct food contact regulations.

All models are now available with a print speed of 60m/min, further improving on what Screen says is the L350UV’s already best-in-class productivity.

The L350UV is distributed in Australia & New Zealand by Jet Technologies, which has a long partnership with Screen, and continues to run a demo-centre in Sydney with an L350UV for trials and client demonstrations.

Jack Malki, director of Jet Technologies says, “Many people doubted inkjet, but now with so many successful installations here and abroad, clients can see that the L350UV is a robust solution that allows them to print almost any material, without priming or special rules, with high productivity and on a reliable platform. The additional models mean that the L350UV+ will be a winner in even more markets, and shows Screen’s dedication to the platform.”

Esko says the CDI (Cyrel Digital Imager) offers results that before were only achievable in offset or gravure. There is a CDI for every need from narrow web label printing to flexible packaging and wide-format corrugated printing, one-colour printed corrugated boxes to sophisticated multi-colour packaging and even security printing.

New to the Esko portfolio is the CDI Crystal 5080 XPS flexo platemaking system, designed to address the overriding market pressures driven by shorter run lengths and a growing number of SKUs. It requires fast plate turnaround to address this increasing demand for product versioning, and the CDI Crystal 5080 XPS delivers that. It also brings higher quality to flexo, delivering better consistency, and is simple to use for operators at all skill levels.

The CDI Crystal 5080 flexo platemaking system exposes both sides of a flexo plate using UV LED heads. It also combines imaging and exposing into the same compact footprint. According to Esko this results in 50 per cent fewer manual steps, 30 per cent faster access to plates and 73 per cent less required operator time.

Along with Full HD Flexo will be Esko’s Digital Flexo Suite (DFS), offering significant cost savings through the automation of flexo plate production. Layouts are nested are nested economically on the plate to reduce plate and substrate waste. The optimised plate and the corresponding cutting layout are simultaneously sent to a CDI and Kongsberg table. The plate is staggered cut to enable flexo cylinders to print continuous labels on the press. The Kongsberg X20 offers the flexibility of upgrading to add more cutting, creasing and milling tools as business needs develop.

Esko has a local team in the Australian region, providing full training and service locally for all products and solutions.

CHILI publisher is a straight-forward online editing solution that allows any user to easily edit marketing document templates. The software safeguards brand design guidelines while enabling users to tailor other elements on the page to create any type of document that is production ready, and one that fully respects the rules of the corporate ID and the industry.

Chili Publisher brings an incredible ease of use to the table, as it requires little to no graphical experience for users to edit the documents.

The software integrates into a variety of MIS, workflow and business management platforms (eCommerce and DAM for example), which allows for a personalised user interface. It also comes with features like the 3D visualisation tool, generating a direct 3D assessment of the final marketing output. Workflowz says it offers robust functionality with an open API facilitating your own custom integrations – simply intuitive browser based interface, with fully integrated and adaptable UI. And Chili publisher can fit to scale anyone’s needs.

The ease of integration of these solutions into existing workflows, and the connection possibilities they offer with data-driven solutions, make online editing ideal to unlock a wide array of marketing potential in digital packaging, be it customisation, regionalisation or individualisation opportunities.

Going web-to- print has enabled many print service providers globally to offering, import Adobe InDesign files, simple DataMerge for Variable Data Printing, reducing administrative and design time on the enterprise level, only editor could 100 per cent automate the postal mail, production time cut by receiving receptive templates work the service to the solution.

The solution comes with an open API, meaning that the scale of integration can be tailored to your needs and budget. Upon integration, a professional training session is provided to ensure users get the best possible return on their investment. A professional service desk is available to answer any question. A Chili publisher solution can be readily available as of $60,000, complemented with a yearly servicing contract. There are no transaction costs per document or user, and it offers unlimited production.

Connect1to1 UStore is an All-in-one Web-to- Print solution out-of- the-box it is a convenient web portal to order printed products 24/7. It streamlines order acquisition, production and fulfilment. The product also supports multiple product types, enables print buyers to upload or submit documents, supports static, customised and variable documents via catalogue. It has a integrated workflow automation with JDF/JMF job ticketing.

The product increases print volume while lowering operational costs, it decreases manual processes and increases operational efficiency. UStore is a modern web-to-print solution where storefronts can use responsive design to support multiple devices and screen sizes. It Includes uEdit HD – the high-definition WYSIWYG document editor. UStore has modular solution supports future business growth. It has optional Cross-Media add-on enables multichannel campaigns to be sold on the storefront and other options include personalised imagery, dynamic charts, access to APIs and more.

UStore is a XMPie product providing an end-to-end hardware and software solution. UStore can be added to any PersonalEffect solution – Turn-key or Enterprise. When a customer has specific requirements and needs to build a custom configuration, add uStore to enable the Web-to-print functionality. It has custom applications with bespoke functionality, customers who plan to build custom functionality on top of the off-the- shelf capabilities provided by UStore, should consider uStore.

Web-to-print and Cross-Media are needed from the beginning, if a customer needs both web-to-print and cross-media capabilities, go with uStore + TransMedia [Pro] or uStore + Enterprise Cross Media

As uStore is scalable it is for a customer that needs a scalable, fault-tolerant configuration with web-to-print functionality. XMPie Sales is ready to help assist with uStore deals. Due to the complex nature of custom configured solutions, XMPie Sales can assist when necessary.

UStore makes the products and services offered by service providers and print rooms convenient to order and accessible any time, from anywhere.

Key benefits include allowing print buyers to upload documents for printing, allows print buyers to customize and order products, streamlines order acquisition through product templates, increases productivity and efficiency and feeds the beast – drives more print volume.

Key benefits for the print buyer include print buyers get instant pricing – no waiting for quotes, print buyers can place orders when it is convenient for them.

There is onsite training available with product upgrades to new features and capabilities and critical software corrections. Users will have access to a support and training portal, highly trained global support personnel, knowledge based website, training portal, direct line to research and development where necessary and technical support via remote login

Finance is negotiated via a third party, and uStore is priced at $50,000.

With printIQ you get far more than just an MIS. With printIQ the web-to-print functionality is built directly into the core product. There’s no separate bolt on or third party software, it’s simply part of the base product and everyone accesses it. Production-staff manage the factory whilst customers quote, order and track, all from within same application. With no software to install, no separate web portal or online ordering system to add on, printIQ certainly does represent a quantum shift from what most printers are doing right now.

The company says the main differentiator between printIQ and other W2P solutions is that printIQ is more than just a shopping cart. It combines the power of the printIQ pricing engine with an integrated online ordering process to give your customers an online experience specifically designed for the complexities of print.

The combination also removes the need to integrate the online order with your MWS. With printIQ, the online order hits production as soon as the customer confirms it. This is a smart move given that integration is rated as one of the biggest frustrations with IT systems.

As a further extension to its W2P functionality, it has a range of modules that offer customers all the touch points that they require in the modern business world. These optional tools are designed to connect to an array of options, from file verification, to VDP, web applications, and even other printers.

IQconnect-SmartSite allows you to take the best out of your marketing orientated website and power it up with printIQ as the shopping cart to create one or more, online entries into your business.

IQconnect-Chili Publish offers a template option in addition to the standard web2print functionality within printIQ. With IQconnect- XMPie you can connect printIQ to XMPie with real two-way communication. With this seamless integration, printIQ will consume the XMPie data and generate a job or sales order directly within printIQ.

IQconnect-Integrate is a series of fully documented and comprehensive API’s, that allow you to connect printIQ directly to both Hubspot and Zoho. Its APi’s are also available via Zapier, so you can connect hundreds of web apps apps, making it easier to automate tedious tasks.

IQconnect – Link extends your product offering beyond your own factory walls and into the plants of other printIQ users. You can offer signage, POS, wide format, digital, offset and ganged products from within your own website to add value to your customers and to instantly create new sales opportunities on the fly.

IQstore-plus is the printIQ sales order module that allows you to offer a pick and pack item to your customers online. Whether it is an item that you have manufactured or a straight pick and pack item, IQstore delivers a feature rich order process complete with a robust workflow to ensure efficient warehouse management.

The Vpress Web2Print CorePrint is a rich W2P solution seamlessly integrated into the Tharstern MIS. Over the last 15 years, Vpress has brought together experts from the print industry and the technology sector to create one of the world’s most successful Web2Print systems, Coreprint. This proprietary technology is not based on another company’s software or hardware solution. This independence gives Vpress the flexibility needed to develop robust features and functionality that meets customers’ evolving business needs including: Web2Print, process automation, branded online portals, and workflow automation.

The Vpress focus on technology means the features of Coreprint can keep up with the fast pace of technical and business developments happening today, including mobile, workflow integrations, and support for international languages.

Coreprint is used by more than 3,000 companies in more than 68 countries. It is a well proven service, agile in a diverse market and needs little or no training in its implementation and use; something few others in the market can also claim.

Coreprint combines the best of all models as a cloud-based SaaS service, fully integrated with the Tharstern MIS which can optionally be hosted in the cloud or installed locally as an enterprise MIS system integrated to downstream workflows for pre-press, press and post-press functionality.

Coreprint also offers an optional webservice for open integration so you can take the Coreprint engine and integrate it with any website or platform or SSO (Single Sign On), creating your own web2print solution to use and sell as your own. Coreprint has a low cost of entry with a transaction based pricing model.

With a unified Coreprint Tharstern MIS workflow the end user is working with a dynamic interface, signing off their artwork at any time and sending it stright to the MIS produciotn workflow. So even though variable print products are a commodity the printroom becomes a natural extension of the customer’s desktop. This creates stronger ties with customers as there is a shared ownership of the online solution. End to end automation means volumes increase.

With the cutting features in its CJV150 and CJV300 series, Mimaki says it is leading the way for print and cut devices. Mimaki is producing print and cut or cut and print all-in-one units that suit the growing market demands for this type of technology.

The kinds of technological advancements that Mimaki has brought to the sector have enabled signage and print companies to look beyond traditional applications and move into fresh markets and create new revenue streams.

In the past these products were seen as one dimensional items, producing signs and stickers. But now Mimaki is seeing its users producing many different applications including heat transfer items for apparel and promotional items.

Mimaki has seen the shift in applications and has designed features to suit the cross-sector markets.

Brad Creighton, national sales and marketing manager, Mimaki explains, “Think about this. Heat transfer film can be thin and difficult to cut, especially once printed. Heavy saturation of ink can start to distort the film before the cutting process. To have the option to cut this material first then print in a production environment shows Mimaki’s forward thinking about industry awareness and the needs of the market. The Mimaki CJV150 Series high-speed, large-format, solvent printer/cutter devices go beyond extraordinary to deliver a wide range of applications.”

Creighton says that specific Mimaki innovations target new capabilities for owners. He says, “For instance, eco-solvent inks in a variety of colours, including silver; and advanced printing technologies, means you can produce anything in a single unit that fits your workflow.

“Also, precision cutting capability gives you the ability to deliver custom and short-run items such as labels, T-shirt transfers or package prototypes. With the Mimaki CJV150 Series quality, colour fidelity and flexibility plus cutting capability you will go beyond the expected, to increase your business and deliver more than your customers can imagine.”

Based on disruptive UVgel technology, the Océ Colorado 1640 is the first wide format graphic arts roll-to- roll printer developed by Canon. It prints 64” wide on all sorts of flexible media, coated and uncoated.

Canon says it is designed for breakthrough productivity, offering never seen before automation capabilities, superior image quality in a wide application range.

UVgel ink technology takes the best of eco solvent, latex and UV to produce a high quality wide gamut odour free instant drying ink. It has a top speed of 159sqm per hour in production mode, and delivers high quality POP prints at 40sqm, faster than any competing system in this segment says the company.

The Colorado 1640 also produces instantly-cured prints on a wide variety of media including heat sensitive media and saves money with segment leading low operating costs.

Canon is pitching it between the lower cost eco solvent printers and the high cost UV inkjet systems. Pricing has not been finalised but it is expected to be under $100,000. Ink costs per litre will be comparable with other inks, but Canon says in real terms printers will be paying between 20 per cent and 40 per cent less for their ink.

Colorado 1640 caters for both indoor and outdoor applications. It delivers a large colour gamut, similar to solvent inks but combines this with the environmental benefits and safety profile of latex and UV-cured systems. Resulting in odourless, VCL-free, durable, colour-fast, high quality prints even on the thinnest, most heat-sensitive media. The UVgel technology features thin ink dispersion with almost no discernible physical profile on the media surface.

The new UVgel technology is a UV curable ink that instantly gels on contact with the media. Canon says it is has an advanced self-aware piezo-electric printhead technology, an LED-based UV system curing without any damaging heat to the media, and continuous printhead nozzle monit-oring with performance compensation.

EFI VUTEK FABRIVU 340 DIGITAL FABRIC PRINTER

EFI says that the Vutek FabriVU 340 digital fabric printer (on show for the first time in Australia at PacPrint 2017 on the Starleaton Stand E30), offers everything needed to produce high quality images at production level speeds—all while keeping running cost low and profit opportunity high.

According to the company print providers can now drive their businesses growth with soft signage and produce dazzling displays, high-density backlit signs and more with ultra-high resolution, ultra-high speed printing. Thanks to sophisticated EFI inkjet print technology, this printer produces robust soft signs and fabric displays that retain the drape and soft hand customers prefer, while still, according to EFI, creating spectacular graphics that can be washed and dried without wrinkling, folded without leaving marks, and that can be reused time and time again.

The EFI FabriVU 340 can print direct to textile or onto transfer paper, and changeover from one to the other is fast and simple. This means users can offer customers more choice in textiles while also saving money by using lower cost substrate materials. The FabriVU range of printers use genuine EFI water-based CMYK disperse dye inks to print on fabrics weighing from 40 to 300gsm, and paper weighing from 40 to 160gsm, to produce dramatic, four-colour fabric display graphics with a wide colour gamut and deep colour saturation. EFI says it is ideal for producing flags, banners, wall coverings, backlit displays and other high-end display graphics.

EFI FabriVU innovations include a patented ink recovery system giving up to 95 per cent of ink saving, direct to fabric or paper transfer, printing speed up to 400/500sq m/hr, a small footprint, automatic self-cleaning functions, high efficiency dryer, and a wrinkle detect protection system against costly head strikes.

The EFI Vutek FabriVU 340 offers maximum production speeds up to 500 sqm per hour, production image quality of 250 sqm per hour and POP image quality at 165sqm/hr.

Epson’s signage and décor printers have been designed to produce superior output with faster, more efficient, and cost-effective operation. They are compatible with an enhanced range of media including the full range of paper, canvas, film and vinyl substrates. Epson says they produce images that are brighter, and more durable, have a higher gloss level and gamut range than competitors, and can be used for producing indoor POS or outdoor signage, back-lit displays or window decorations, banners or vehicle decals, wallpapers or floor finishes, posters or labels, our printers can do it. A range of models suit different production volumes and output requirements, all with easy loading, simple operation and reduced running costs.

The performance of the SureColor S80600 produces output quickly with Dual Print Heads, an extended nine colour ink set, and optional white or metal ink. It comes with media support, supporting paper, canvas, vinyl and film stocks, in widths up to 1626mm and thicknesses up to 1mm, in rolls up to 45kg and 250mm in diameter.

It has a nine cartridge Epson UltraChrome GS3 ink enables prints with high gloss and a colour gamut Pantone certified at up to 98 per cent. It can also be configured with additional white or metallic ink.

It uses the latest PrecisionCore Printhead, new UltraChrome GS3 ink, improved MicroWeave and LUT, self-agitating ink lines, improved paper path with upgraded feed management and a new Advanced Auto Tension Control System.

Epson says SureColor uses superior integration, compact design with flexible networking, suits installation in a wide variety of operational environments, runs off a standard 240V power supply, and can be driven by a variety of third party rips.

It is easy to use as it can be loaded by a single operator with auto media set-up and skew correction, new see-through platen cover with integrated lighting, upgraded control panel and new Epson control dashboard management software.

It needs less maintenance with its new self-cleaning printhead and air circulation system with mist extraction.

It has reduced production costs using new low cost 700ml ink cartridges with reduced ink and power consumption, ships with an integrated auto take-up and drying unit, supports remote management, remote auto status and error reporting.

SCREEN GP TRUEPRESS JET W3200UV

Screen GP was running live sign and POP work on the latest version of the Truepress Jet W3200UV MkII flatbed UV printer, with roll-to-roll option, at PacPrint. The R2R option prints full 3200mm roll widths and when not in use, tucks neatly away under the bed.

Now capable of up to 230sqm/hr in billboard mode, where images are viewed from distances of five metres or more; for sellable close-inspection commercial work, 150sqm/hr is achievable. The 3200UV Mk II’s finest resolution is a 22-pass superfine photo mode for what Screen says is stunning photo-realistic results at 15 sqm/hr.

The seven-colour inkset is CMYK,Lc,Lm plus white and, by controlling the UV ink curing speed with the use of a shuttered system, matte, silk and gloss surface effects can be achieved from the same inkset.

Standard bed size is 3200mm x 1600mm, but a new option is a larger bed skin that boosts maximum size up to 3200 x 2000mm. The twelve 3200s already installed in the ANZ region all feature automated nozzle mapping and cleaning which saves considerable time and operator intervention.

The bed of the W3200UV is ultra-flat and features retractable register pins with six-zoned vacuum areas for says Screen perfect registration of printed boards. Vacuum levels can be controlled to ensure lay-flat of lightweight materials and even boards that may be distorted and require heavier vacuum to hold down.

Screen GP backs the W3200UV with local factory-trained technicians and access to Screen and Inca’s global resources. Comprehensive training is provided at each new site, with a new one to be announced shortly in Melbourne.

Built by Screen GP’s Inca Digital subsidiary in the UK, the device uses Screen’s own inks for flexibility, adhesion and wide colour gamut.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter