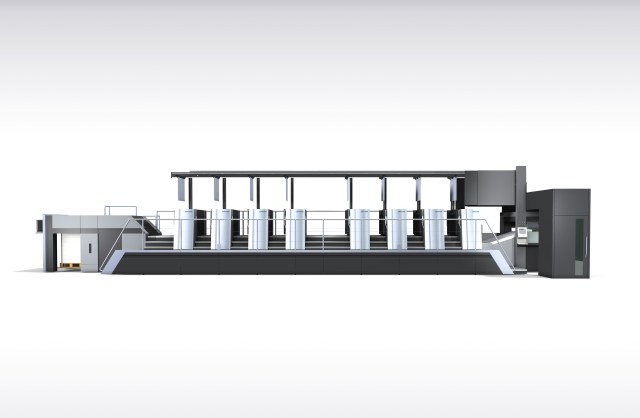

Heidelberg has taken the wraps off its latest press – the new Speedmaster CX 104 – in a world premiere.

At the company’s ‘It’s Showtime’ digital customer event, it unveiled the press in its core business of sheetfed offset printing, looking to further build on its strong position in the expanding packaging segment and meet the growing demands for flexible printing systems with a variety of automation solutions and variants in the commercial sector.

The launch also comes a year after unveiling the drupa 2020 generation of presses, emphasising its innovative strength and technology leadership in a challenging market environment.

The new Speedmaster CX 104 sheet format press aims to offer commercial, packaging, and label printing customers access to sheetfed offset technology.

When selecting equipment variants, Heidelberg said customers benefit from the system’s free scalability, which extends through to Push to Stop functionality – and also from tailored configurations with as many as 15 printing/coating units.

“Heidelberg is investing in the industry’s future. With the new, intelligent Speedmaster CX 104, we’re making our customers and Heidelberg itself far more competitive,” Heidelberg CEO Rainer Hundsdörfer said.

“We’ve developed the press for a broad cross-section of customers and a wide range of applications to target the vast market potential. With our new universal press in the 70 x 100 format, Heidelberg is making state-of-the-art sheetfed offset technology available to a large number of print shops worldwide.”

Intelligence assistance systems

The Speedmaster CX 104 boasts a new, ergonomic design and offers a completely new operating philosophy (Heidelberg UX), together with a host of assistance systems included as standard.

Heidelberg said this provides the “best possible support” for operators at the Prinect Press Center XL 3 control station and at the press itself.

To ensure make-ready times are always kept short, the Intellistart 3 system automatically determines the make-ready processes required for the jobs to be produced. This involves continuously monitoring the press status and comparing it with the upcoming jobs. Intellistart 3 initiates the make-ready process and carries it out automatically.

Intelliguide and the Intelliline colour-controlled LED elements on the printing and coating units alert operators the press operating status at any given time and indicate any manual intervention that is required.

The newly developed Intellirun software also takes operator navigation beyond the make-ready process, providing a preview of several planned jobs.

It also features a number of assistance systems based on artificial intelligence, such as Wash Assistant and Color Assistant Pro and various Prinect colour measurement systems.

A new coating unit

Another key feature of the Speedmaster CX 104 is its new coating unit. It is based on XL technology, which places the focus on simplified operation, faster make-ready, and a further improvement in coating quality.

Heidelberg said accessibility is optimised as key elements of the press have been changed. It said a 30 per cent lower roller weight of the anilox roller makes the changeover process more ergonomic and far faster.

The company also mentioned that the new coating blanket cylinder will make changing coating forms easier and up to 25 per cent faster. A combination clamping system for coating blankets and coating plates also aim to maximise the number of possible applications.

The pairing of a new, compact bearing unit and a new chambered blade concept ensures homogeneous application of coatings, even at the highest speeds.

The Speedmaster CX 104 is also the business’ first press to use the new “pulse laser process” (PLP) screen rollers manufactured by Heidelberg as a standard. This process with targeted laser pulses enables gentle engraving, which results in homogeneous coating surfaces and thus uniformly high gloss levels.

Innovations in inking/dampening unit

Additional functions are also available for customers looking to further boost the performance of the inking/dampening unit, especially in UV printing.

For example, Heidelberg identified that integrated ink mist extraction cuts pressroom emissions, in particular, at high printing speeds.

An automatic ink agitator also keeps the viscosity of the UV ink constant. In addition, an additional washup solution supply is optionally available for mixed operation with conventional and UV inks.

The Auto Protect option protects the rollers in the inking units without a colour assignment by applying Saphira Roller Protection Liquid. Intellistart 3 controls this process automatically based on the job data and printing unit assignment.

This also applies to deep cleaning – another extra – which is automatically suggested when switching from dark to light colours so that the operator can complete other tasks in parallel.

“Series production of the Speedmaster CX 104 has already started and anyone anywhere in the world who is interested in ordering the new press can do so,” Heidelberg Speedmaster CX 104 product manager Florian Franken said.

“A number of European pilot customers in the various market segments are already working successfully with our new solution and are reporting productivity gains of up to 20 per cent, which exceeds even our own expectations.”

Heidelberg has also launched a new Speedmaster CX 92 which features a new, ergonomic design, newly designed coating unit, and the innovations in the inking/dampening unit.

This model, too, comes with the new Press Center generation and Intellistart 3 as standard. With the launch of Prinect Inpress Control 3 and Intelliline, autonomous printing based on the Push to Stop philosophy is now possible for the first time on this model of the press.

In addition to the cost-efficiency achieved by using 20 per cent less printing plate material, process efficiency is also improved as a result of faster make-ready and a reduction in waste, according to Heidelberg.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter