At drupa, Durst launched products across five key platforms including large format, label printing, water-based printing, digital corrugated printing and folding carton production.

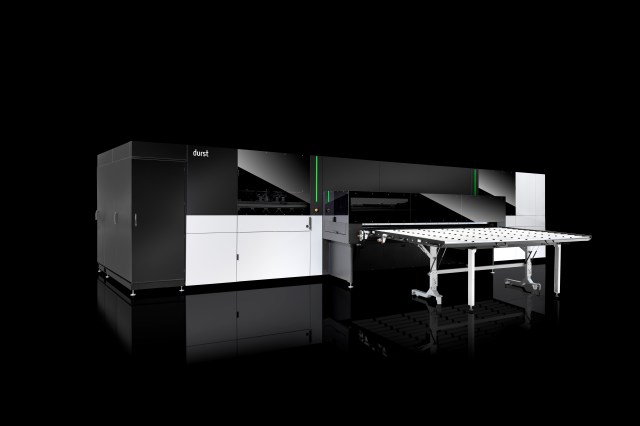

P5 SUPER MULTI PASS

One of the most important launches in the Durst portfolio was the P5 SMP (Super Multi Pass) for the Sign & Display, POP/POS, Corrugated Packaging & Display and Industrial Decor sectors. The hybrid LED Super-Multi-Pass printing system combines efficiency and productivity with maximum versatility. With a print width of 3.5m and a maximum productivity of up to 2,000 square metres per hour, the P5 SMP achieves an annual capacity of 5 million square metres, setting a new benchmark for high-volume digital printing. As a hybrid solution, the P5 SMP can process both roll and sheet material and has the versatile functions of the P5 platform.

Durst vice president – sales, Christian Harder described the new P5 SMP as the “pinnacle of efficiency, speed and quality in graphics, displays, corrugated and industrial decoration”. “We successfully introduced the P5 platform in 2019 and today we offer a complete product portfolio comprising hybrid as well as dedicated roll to roll printing with UV inks in various widths and various speeds.

“This year at drupa, we proudly introduce a further enhancement to the P5 series. The P5 Super Multi Pass delivers a new peak in productivity and is tailor made for the sign and display and corrugated display printing market. The new P5 Super Multi Pass will be available in the various levels of automation empowered by our software solutions to further enhance the production process.”

Durst Oceania managing director, Matt Ashman said he believes the new P5 Super Multi Pass sets new standards in terms of productivity and quality.

“The P5 Super Multi Pass is a game changer in the graphics, signs and display and corrugated packaging markets,” Ashman said.

“There are a number of features and benefits available with the new P5 Super Multi Pass that will make the product attractive to printers looking for the very best productivity.

“Our vision was to develop a Super Multi Pass printer with the highest possible productivity but without limiting the proof of benefits of the current P5 portfolio.

So in a nutshell, we took all of the best features from the P5 portfolio and super charged it.

“We also continued on our mission to reduce required set-up times as well as seamless integration of different support systems such as automated corrugated guides, accurate image positioning, easy head exchange and adjustment as well as the important integration of an improved and flexible feeding and stacking automation.”

The P5 SMP will also feature LED drying and new UV ink formulations.

“With this machine we will be using UV ink since we want to be versatile and allow our customers to print on a wide range of different substrates such as rigid, carton and various banner materials.”

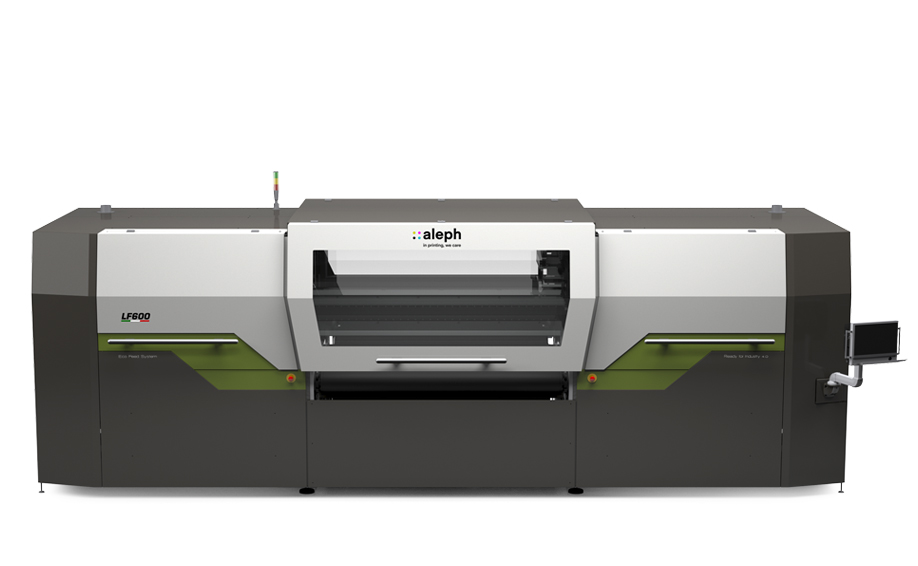

ALEPH LAFORTE 600 PAPER

In late 2023, Durst acquired the Como based printing company Aleph specialising in advanced direct-to-fabric and direct-to paper inkjet printers for the textile and visual communications categories.

On display at drupa 2024 was the Aleph Laforte 600 Paper, which was designed for poster and billboard printing. In its most powerful configuration, the printing system achieves an output of 1,000 m2/h and reaches a new level of quality in poster and billboard printing with six colours and 1,200 dpi.

According to Durst Oceania managing director, Matt Ashman, the acquisition of the Aleph range of products is a logical expansion for the company to expand its positions in the field of water-based and sustainable printing technologies.

“Aleph provides the environmental and sustainability credentials printing businesses have been looking for with the ability to print with 100 per cent water-based ink for posters and signage as well as textile applications. Brand owners are always looking at the most sustainable printing and media solutions and what is more sustainable than paper.

We look forward to announcing the first Aleph installation in Australia shortly,” Ashman said.

KJET

Durst has launched the KJet at drupa 2024 – the successor to the XJet. The KJet is a new hybrid solution for label printing and is the second product developed in conjunction with Italian family-owned manufacturer OMET.

According to Durst Oceania managing director, Matt Ashman, the KJet is an end-to-end solution that combines OMET’s dual servo flexo printing units with Durst’s state-of-the-art RSCi inkjet technology.

“In addition, modules for finishing and further processing such as cold foil stamping or die-cutting units canbe integrated into the KJet. This flexibility opens up an enormously broad application portfolio for the KJet. The configuration of the KJet is tailored to the specific requirements of each customer,” Ashman said.

Durst sales and director for labels and packaging, Thomas Macina, said the combination of digital with flexo offers an innovative hybrid solution that maximises productivity and flexibility, enabling printers to select between flexo or digital printing, thereby optimising efficiency and reducing costs while meeting evolving market demands such as personalisation and just-in-time deliveries in a single pass.

“We have been leading the inkjet label printing market for many years and we provide entry level solutions up to industrial needs at 100 metres per minute and 510 millimetres wide. We have been observing a clear market trend towards end-to-end production and this is why we have reinforced our partnership with OMET. The KJet is a perfect combination of a dual-servo cylinder based flexo unit combined with the robustness, efficiency and productivity of the Durst RSCi digital print engine. This provides a new experience to operators in terms of simplicity, minimal set-up time and low waste,” Macina said.

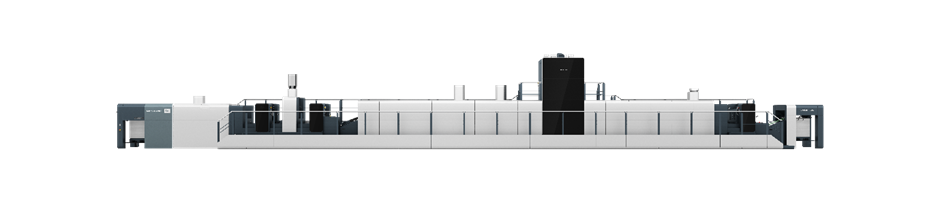

VARIJET 106

On display at an exhibition for the first time at drupa 2024, the VariJET 106 is a significant innovation from the Koenig & Bauer Durst joint venture, which will pave the way for the digitalisation of industrial folding carton production.

At drupa, single pass VariJET 106 was shown in a hybrid configuration linked to Koenig & Bauer’s Rapida offset press technology and workflow as well as demonstrating the latest die cutting and folding gluer technology.

The VariJET 106 was first announced in 2021, and uses water-based inks, so that primary packaging for food can be produced. However, the VariJET 106 is also a promising solution for applications in the pharmaceutical, cosmetics and tobacco industries for the economical production of short to medium runs and individualized packaging.

The VariJET 106 covers the B1 format and achieves a printing speed of 5,500 sheets per hour. The monthly print volume ranges from 500,000 to more than 1 million B1 sheets. Thanks to its hybrid design, several finishing units can be optionally integrated into the VariJET. In this way, the VariJET 106 becomes an end-to-end solution that enables economical and fast production of high-quality jobs.

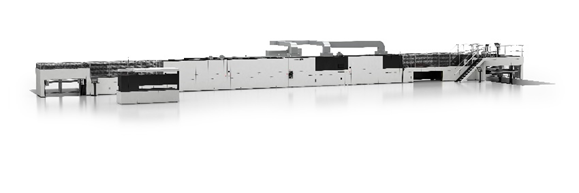

DELTA SPC 130

Another product from the Koenig & Bauer Durst collaboration, the Delta SPC 130 is a single pass digital sheet-fed machine for corrugated markets.

According to Durst Oceania managing director, Matt Ashman, what was missing in industrial digital corrugated printing until now was the colour white.

“Durst is once again taking on a pioneering role in the industry and is launching a water-based white ink for the Koenig & Bauer Durst Delta SPC 130,” Ashman said.

“The use of white with extremely high opacity on brown corrugated board opens up new design possibilities and enhances transport packaging. By overprinting white, a significantly improved image quality is achieved on almost all topliners and at the same time an exact match to spot colours. All inks and fluids used in the Delta SPC 130 meet the current and future requirements of the food industry.

Koenig & Bauer Durst managing director, Daniel Velema said one of the highlights of drupa was the demonstration of the VariJET106 in full production.

“The VariJET106 is a monster of a machine and combines the very best of conventional and digital printing. We believe drupa will be landmark in our journey within the folding carton and corrugated markets.

The tipping point is here. Corrugated and folding carton printers/converters who was to increase efficiency, flexibility and work even more closely with brands and retailers recognise that they need to digitise their production environments.

“As a global leader in digital sheetfed, single pass press systems and software services for the folding carton and corrugated markets – and with the backing of two giants in the packaging and printing industry – we see huge opportunities to grow substantially over the coming years and continue to support and accelerate our customers’ digital journey,” Velema said.

Durst CEO and co-owner, Christoph Gamper told journalists at the company’s drupa press conference that the “little big company” now has over 1000 staff and 295 registered patents.

Gamper confirmed annual sales revenue of 360 million Euros, global distribution of 2.2 million litres of ink with 320 service engineers working across the company’s 33 subsidiaries around the world.

“We invest 7.5 to 8 per cent of our revenue back into research and development, and we have 4000 installations in 72 countries.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter