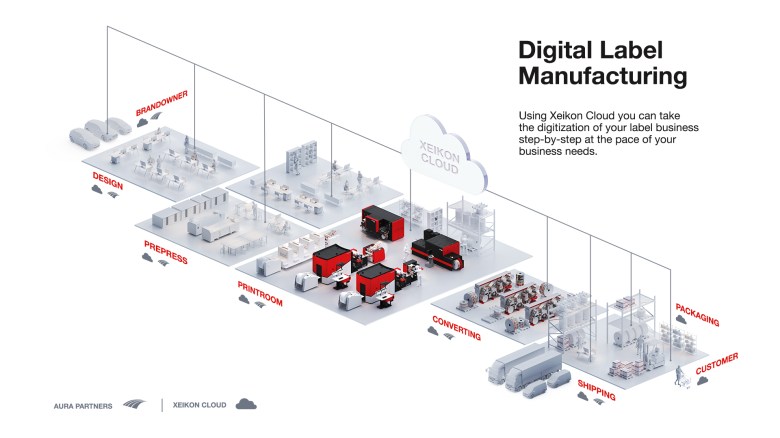

Xeikon has taken another strategic step forward into new areas of innovation, in line with its vision to offer printers and converters a clear and viable pathway to digital transformation.

The company has launched new product introductions in all different aspects of the print manufacturing workflow, including digital production presses, services and workflow management.

Xeikon said these new products take the business to the next level as printers and converters are searching for solutions that will enable them to achieve business growth, provide the highest quality and offer creative products to meet today’s evolving consumer demands.

Xeikon vice-president of marketing Filip Weymans said, “In the last year, Xeikon has launched several new innovations and products. Now, printers and converters are truly able to see our vision materialising and what that can mean for them.

“The careful build and structure of our portfolio is about to bear fruit, and we are now ready to present even more exciting innovations that will open up a way toward a digital future and ‘lights out’ production and manufacturing.”

Xeikon’s innovations include:

Digital production presses

- Xeikon Cheetah 2.0 dry toner technology: Now cloud-connected with man/machine and machine/machine interfaces where the machines are in constant communication with each other, driving and monitoring print jobs with full automation. Earlier this year, Xeikon introduced two new models: the CX30 and the CX50 entry level dry-toner presses. With each cloud-connected solution, operators can monitor print manufacturing from anywhere on the shop floor by viewing the interfaces/dashboards 24/7 on a smartphone or any other device.

- Panther 2.0 UV InkJet technology: New Panther models will include the Xeikon PX2200 and Xeikon PX3300, replacing the PX2000 and PX3000.

- Xeikon’s Label Converting Unit (LCU) series: Within Xeikon’s portfolio, they are specifically designed for converting industries and printing businesses. The LCUs, formally named D-Coat, are also cloud connected with machine/machine interfaces. There are various options to choose from, such as entry level, wide web, narrow web and high-end as well as more modular offerings. With each cloud-connected solution, operators can monitor print manufacturing from anywhere on the shop floor by viewing the interfaces/dashboards 24/7 on a smartphone or any other device.

Services

Xeikon is announcing a selection of new services to add to Xeikon’s already comprehensive Solutions & Services (XSS) and aXelerate programs:

- Xeikon (Business Services) XBS: In real time, Xeikon Business Services can translate data in the cloud from machine to machine and provide all the necessary and in-depth information on a dashboard that is available on any smartphone or device. With Xeikon XBS, printers and converters can check the performance of any press or piece of equipment at any time 24/7.

- Xeikon (Performance Services) XPS: Xeikon Performance Services will be included as a standard for the first six months with all press investments. This is intended to help printers and converters identify which aspects of production need their attention. This software will highlight and visualise any key feature that need adjusting, including maintenance issues, training schedules or applications check. This service will be offered to support customers in their digital start-up phase. It will also provide Xeikon with the information needed to help their customers become operational faster when embarking on their digital journey.

- Xeikon (Colour Services) XCS

Xeikon’s XCS Pro 2.0 is a cloud-connected breakthrough in colour management, it is a unique automated toolbox for the highest quality printed products. Extra capabilities include full automation for ‘on -the -fly’ profiling, colour profile monitoring and adjusting. It is now possible on a Xeikon press to automatically recalibrate the colour profile when an issue arises. The operator is alerted automatically, and the problem is automatically escalated to the production manager if it persists. Importantly, XCS 2.0 can now be used for making colour profiles on a variety of different platforms such as a flexo press, offset press, screen printing with digital or any competitors press. The Xeikon XCS 2.0 also has the advantage of simplifying the process for the printer and manufacturer as it covers all their needs for high-end colour management.

Workflow

Xeikon is now extending the capabilities of its X-800 workflow even further to expand and enhance the range of possible applications. The label version of the X-800 will now include Xeikon VARI ONE variable data workflow and combine it with Panther durable haptic printing and with Xeikon’s FEU (Fusion Embellishment Unit).

“With our latest innovations, printers and converters will be able to address the current and future needs of print buyers and brand owners. Having clear insight into their production environments means they can monitor progress and make quick and flexible decisions on the fly,” Weymans said.

“This is why digitisation can be a game changer. When we install the first digital press at a company’s site, we are with that company every step of their growth journey. They quickly realise the productivity, growth and profit benefits of implementing a fully automated digital print manufacturing process.

“Everyone knows that making changes in a company’s strategy and operations can be difficult. Xeikon stands as the go-to advisor for printers and converters looking to the future for their growth and sustainable profitability.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter